Lagler

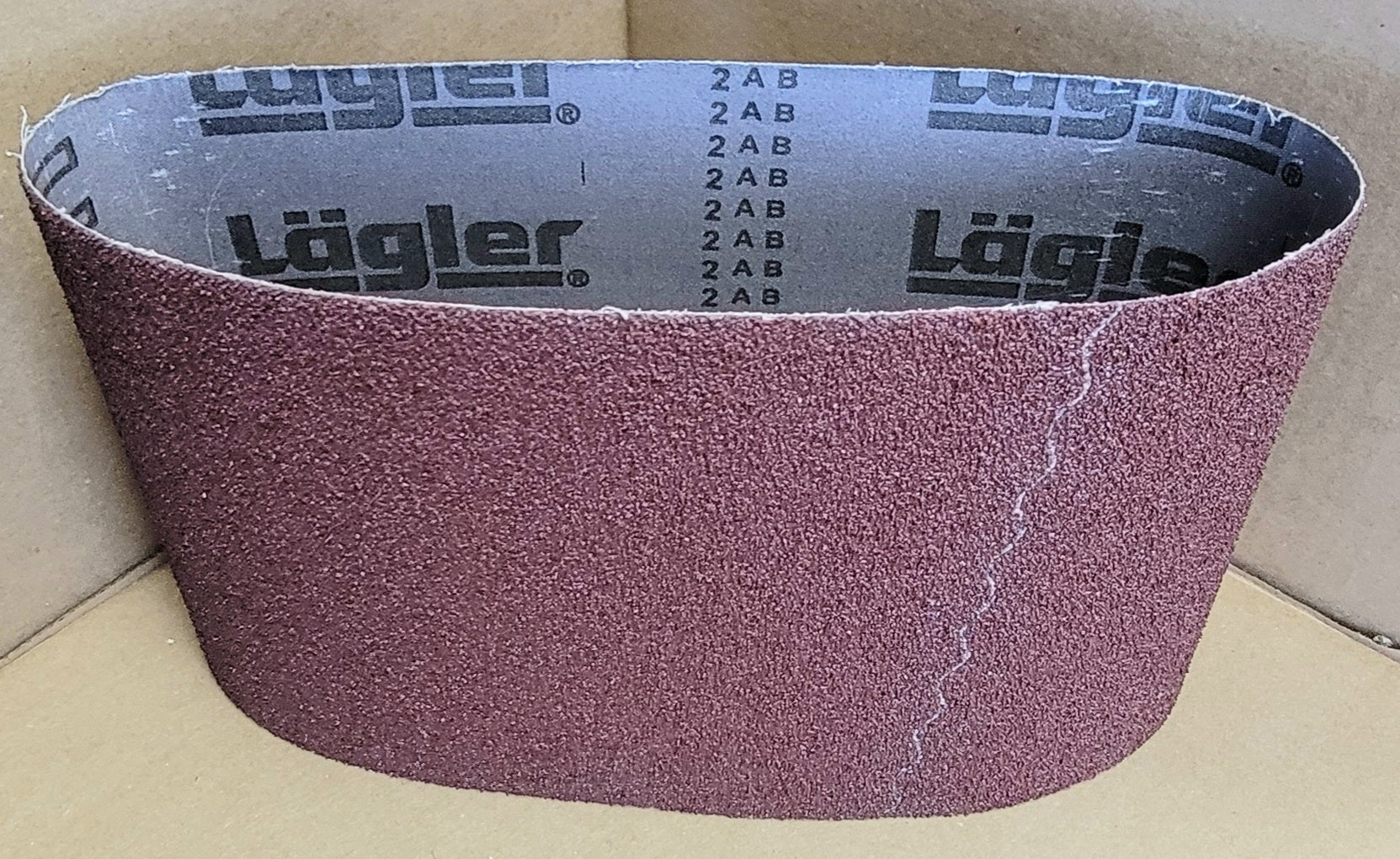

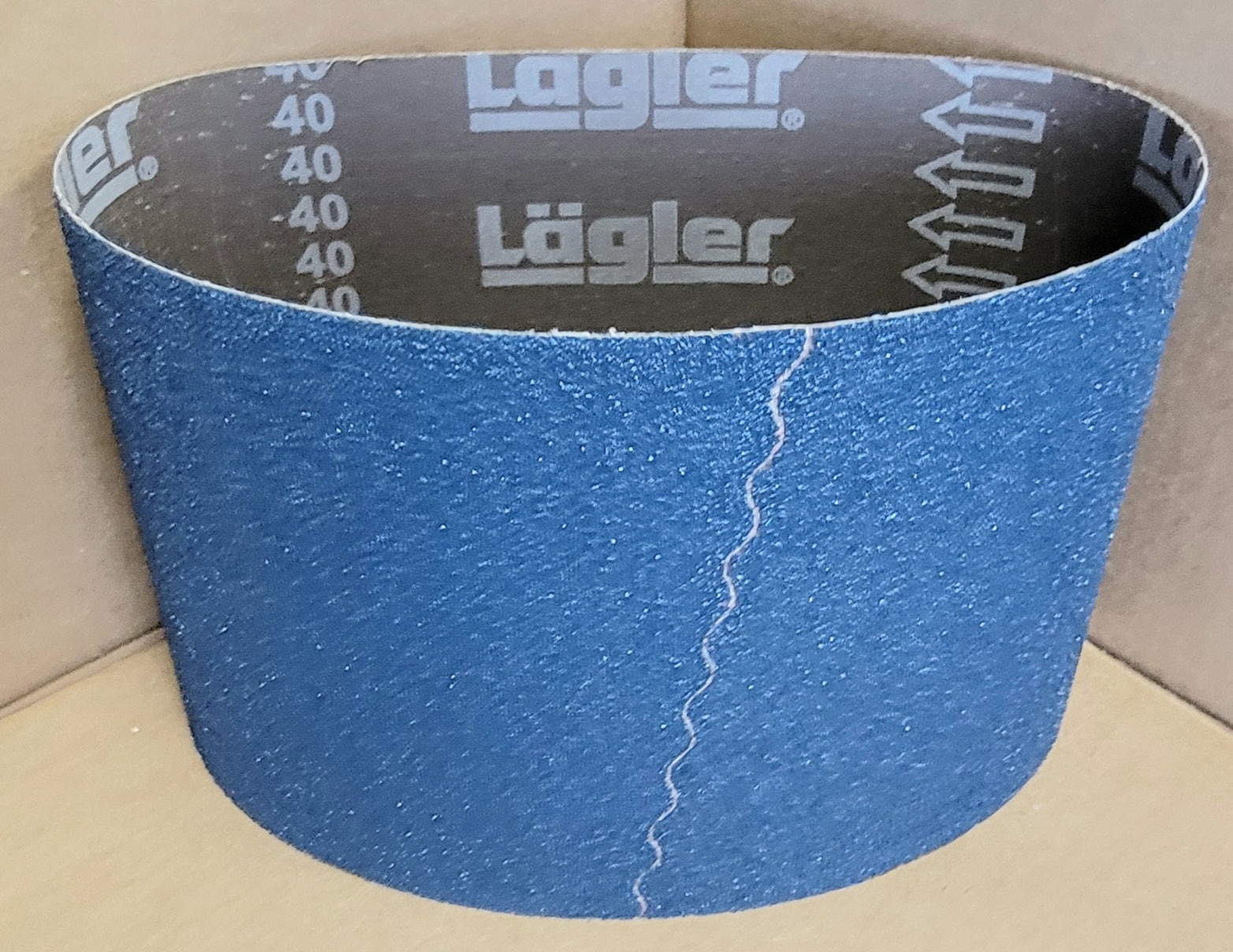

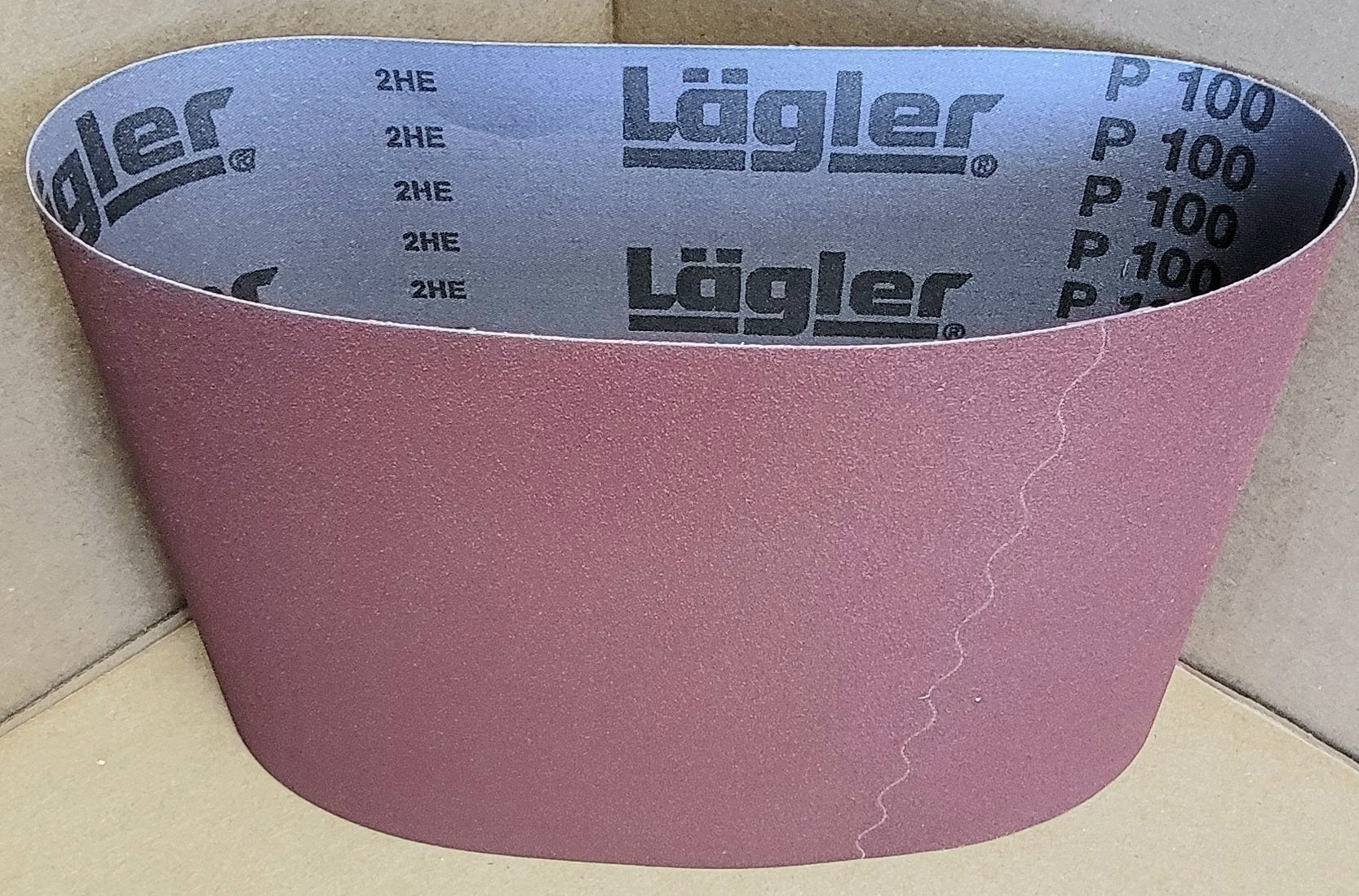

Lagler 8" Belts

Não foi possível carregar a disponibilidade de retirada.

Available in different grits - 16, 24, 36, 40, 50, 60, 80, 100.

Designed specifically for your Lagler Hummel Belt Sander.

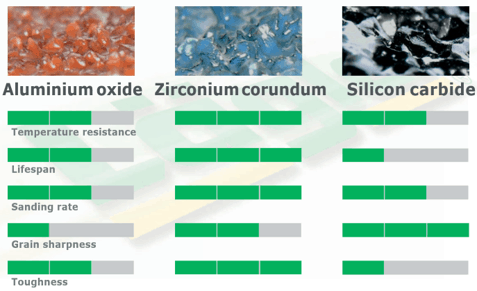

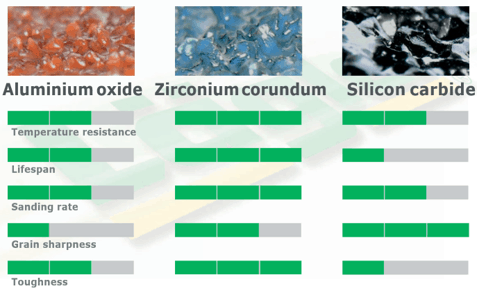

Abrasives Composition

Choosing the right abrasive is one of the most important decisions in achieving a premium surface. Proper matching of the backing, bond and abrasive grain is particularly important for a high quality abrasive.

Backing serves as the base for the abrasive grains and the bonding system.There are generally two backing variations- textile and paper. The greater the loading caused by the sanding process, the more resistant the backing needs to be. The bond fixes the abrasive grain to the backing. A distinction is made between the base bond, which anchors the grain on the backing, and the coating bond, which connects and stabilizes the grains together. Depending on the area of application of the abrasive, softer or harder bonds are used. Generally in the wood sector, synthetic resins are used as bonds, which have a very high resistance to heat.

Abrasive grain consists of hard cutting materials that ensure material removal. The size and dispersion of the individual abrasive grains, as well as the type of cutting material, play a critical role.